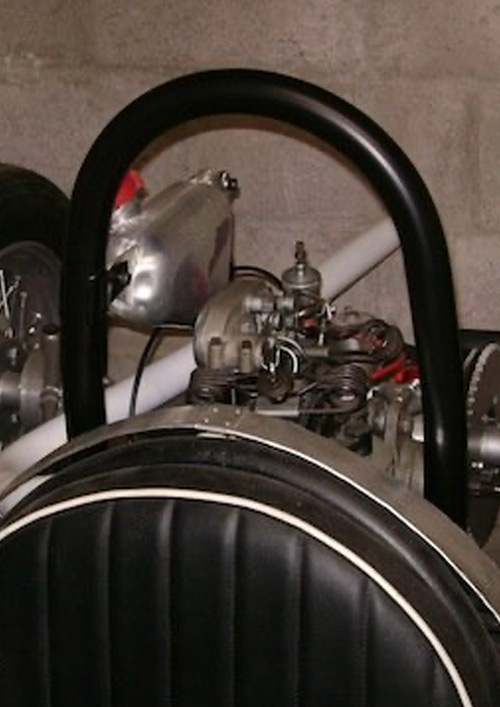

Tube Bending Services

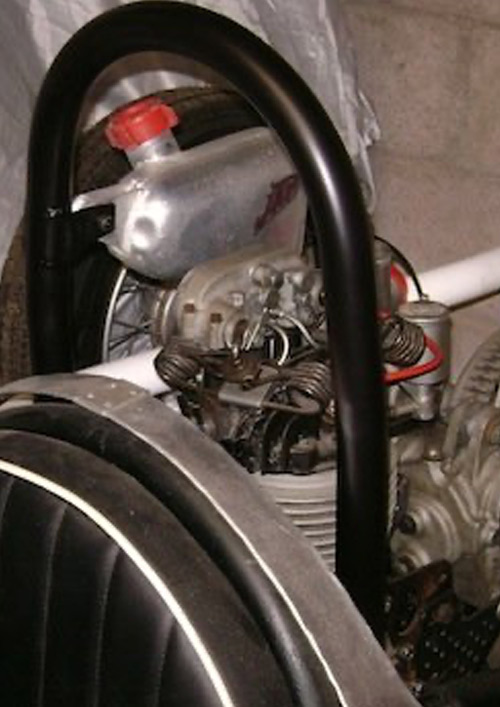

Roll Cages Architectural Bends

Welcome to Tube Bender Limited A midlands based tube bending service producing high quality, bent tube and box section in stainless steel, mild steel, CDS, T45, chrome moly, aluminium, brass, copper and duplex alloys to customers exacting specifications for a huge variety of applications.

Complex accurate tube bending is often outsourced by manufacturers and builders due to equipment costs, and resources , it just doesn’t add up.

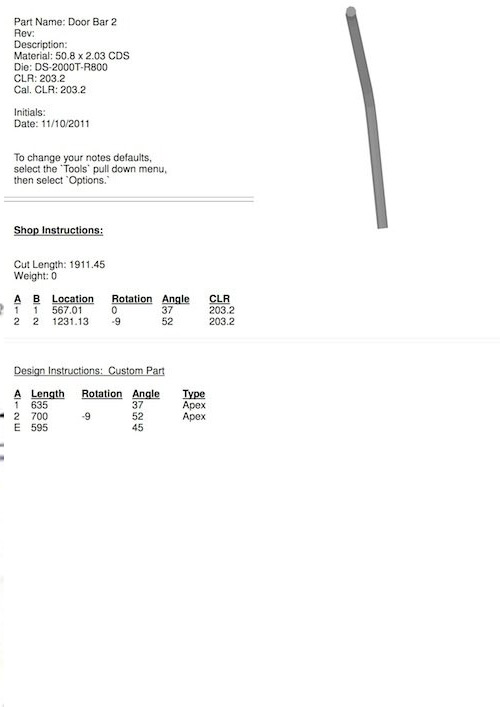

This is where Tube Bender steps in, quick, accurate, outstanding quality production, using one of our state of the art Amob CNC tube bending machines, as used by the worlds largets UK Aeropsace manufacturer, computer aided design delivered for customer installation. The very highest quality bent tube at a fiercely competitive rate with a quick turn around from design, production to delivery.

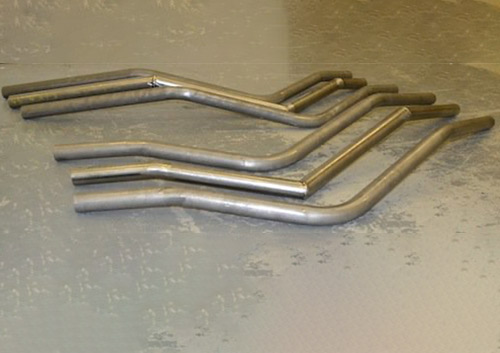

We supply a single bend or multiple bends from our standard stock or a bespoke series of bends in a single length of tube or box section. From a one off to volume production, please do not hesitate to contact us. We can meet your exact requirements with a swift turn around at a very competitive price.

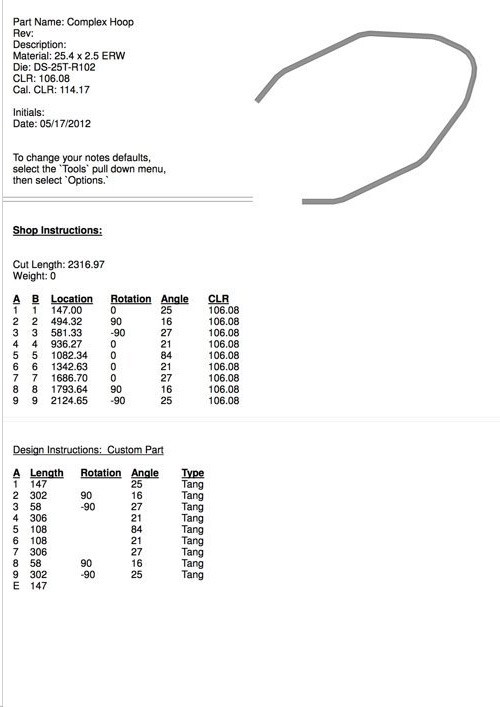

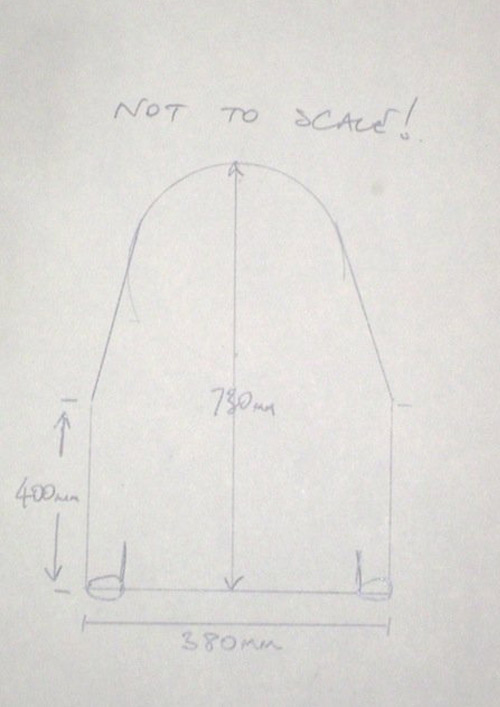

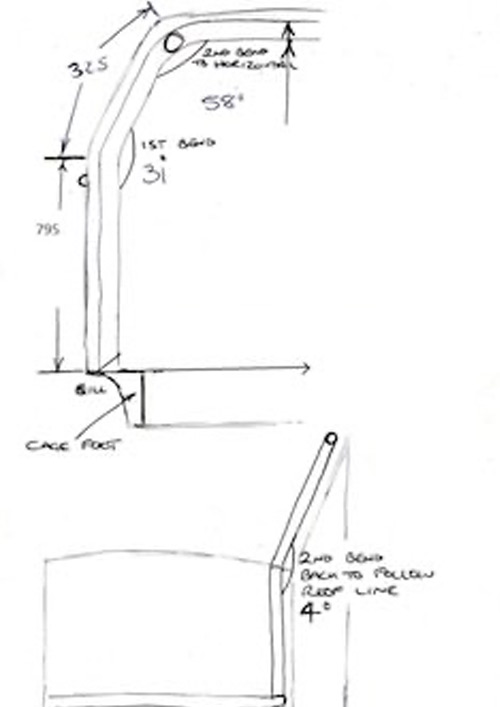

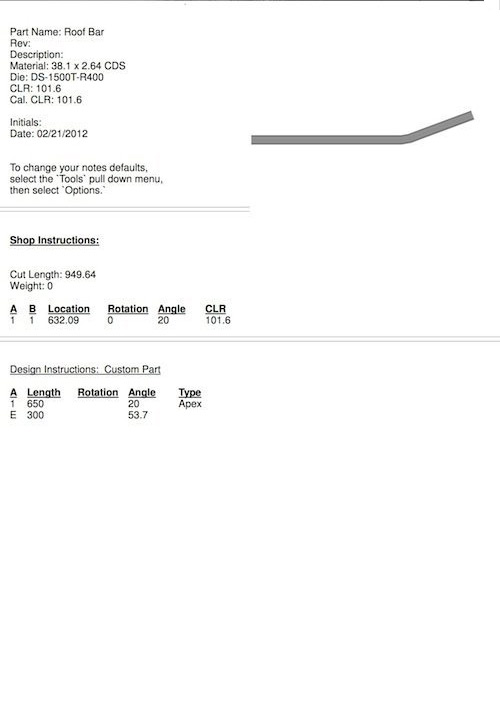

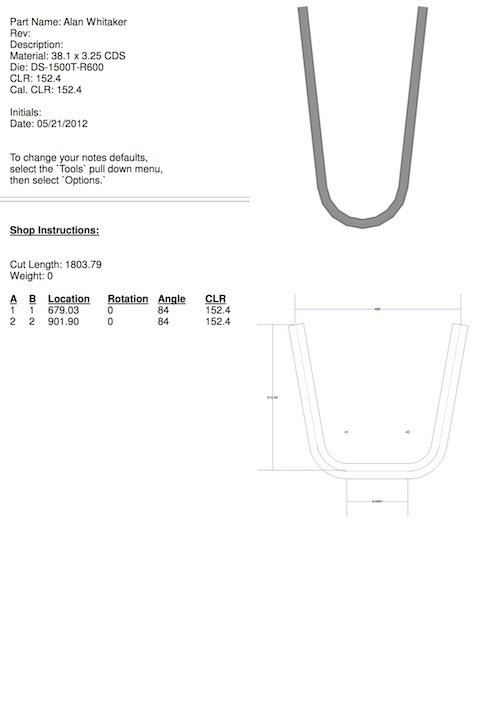

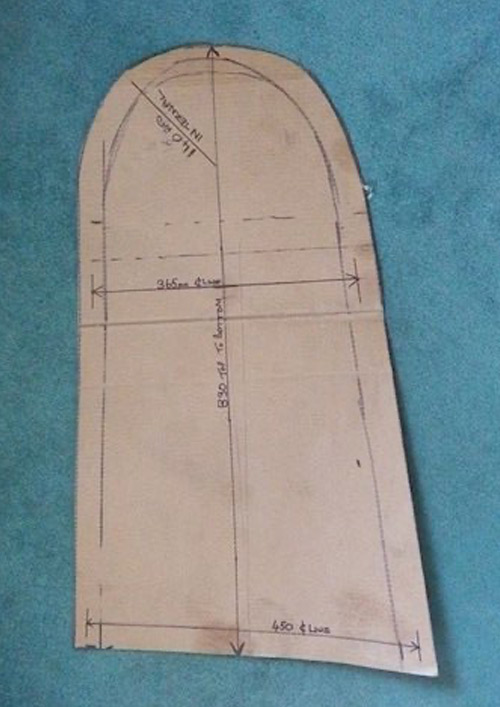

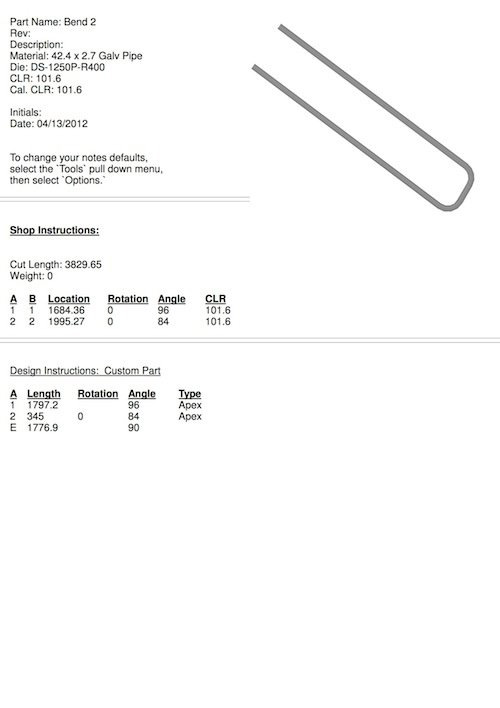

Once we have received your plan, sketch, photograph or drawing, we will model it in and produce a computer designed set of plans which will be sent to you for approval together with cost and lead time. Its as simple as that.

Over the last 10 years, Tube Bender has developed a reputation for quality, value, and a deep knowledge in all aspects of their work.

Formed in 2011, Tube bender has continued to grow and develop into where we are today.

Starting out producing one off and smaller batch orders, we have continued to expand, and now have deep rooted connections in all areas of tube bending. We have long standing partners and customers in both private and public sectors, in many areas of manufacturing, including, but not limited to: Motorsport and Automotive, Marine, Aerospace, Agricultural, Architectural, Pharmaceutical and many more.

We regularly and accurately bend a wide variety of materials, including mild and stainless steel, aluminium and titanium. Using our state-of-the-art tube and mandrel benders, there isn’t much we can’t do!

We are always looking to grow and expand, while remembering our core principals, quality tubes at competitive prices.

The recent purchase of an emob-52 full CNC mandrel bender from AMOB UK, has enabled us to continue to provide these services to our existing customers, with increased capacity for larger production orders in shorter timescales.

Whether it is a one-off custom piece, small batch run, or a large production order, Tube Bender has the expertise to help.

Please get in touch with our team, who are always happy to help!

Best Quality, Best Material, Best Price, Good To Know

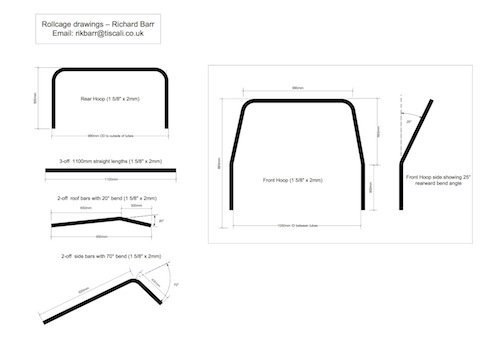

MSUK FIA Compliant Roll Cage

All our roll cages are manufactured using CDS (cold drawn seamless) tube, exceeding the minimum requirements set out by the MSUK and FIA regulations. Do not confuse CDS with inferior blue band or steam pipe used by some other manufacturers, CDS is stronger, lighter, better to weld and specifically manufactured for use in roll cages. We design and produce 6 Point, Fully Fitted, MSUK Certified Internal Roll Cage made to the Blue Book. We issue a full Compliance Certificate for your scrutinisers pack. Don’t get let down by an inferior cage that may well have cost you a lot more.

We have in stock all types of roll cage tube from standard CDS up to T45 and Chrome Moly and can supply this by the metre if required. Please see the items in our Tube Bender Limited eBay store.

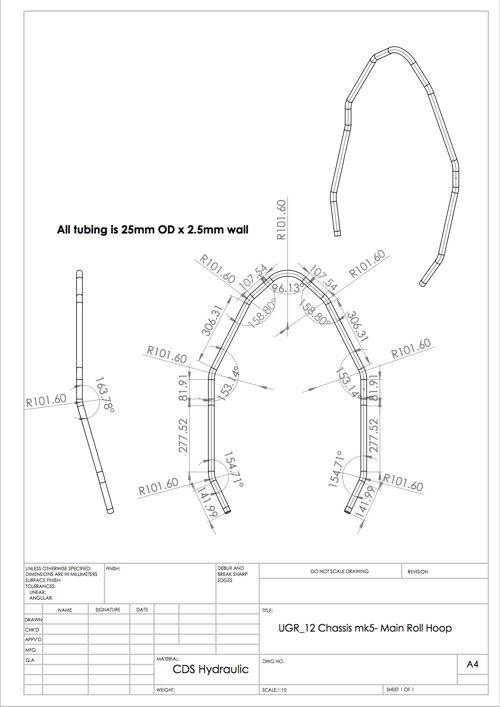

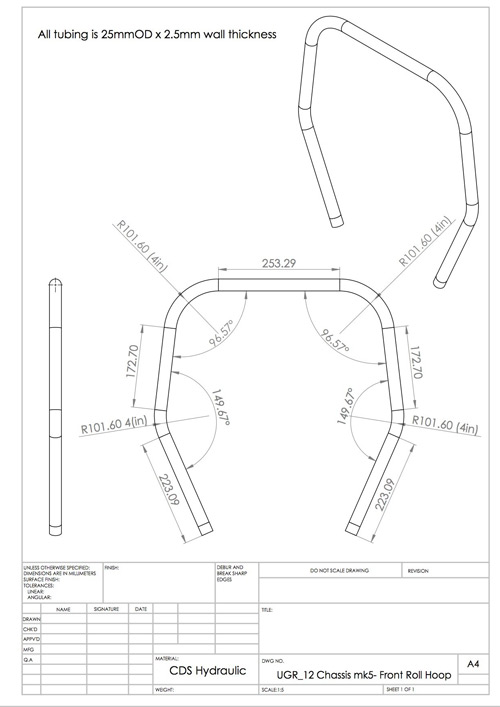

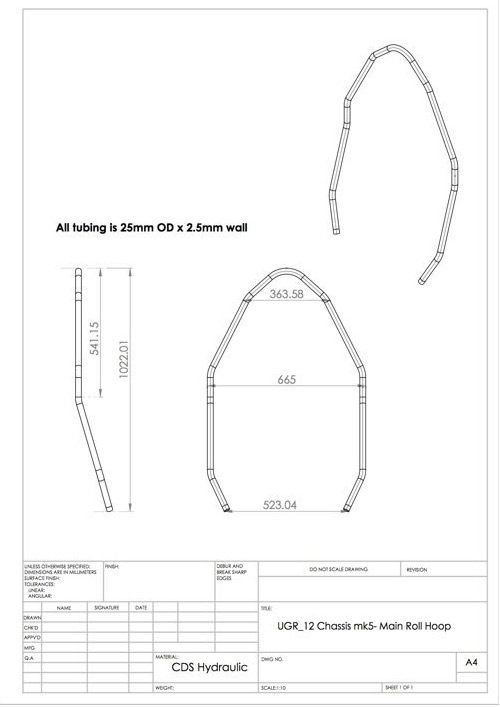

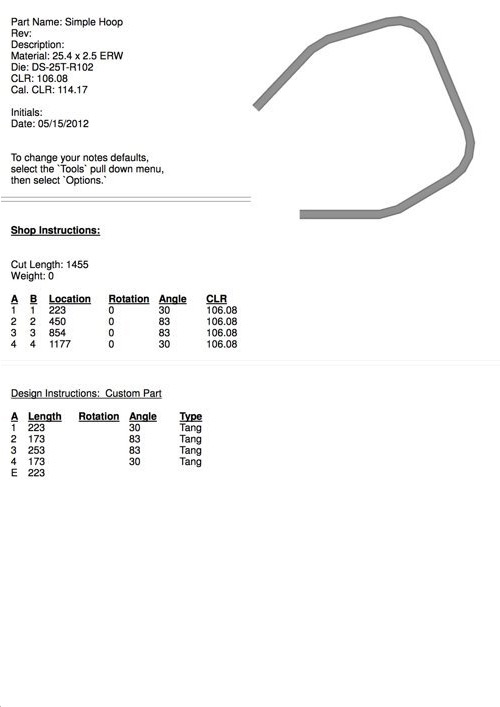

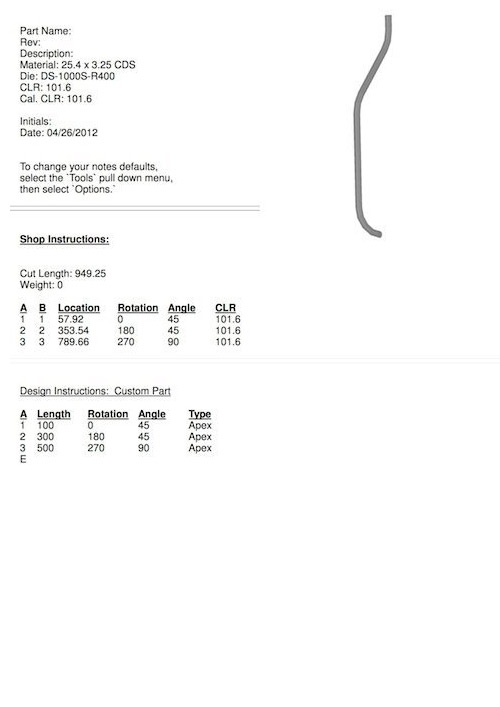

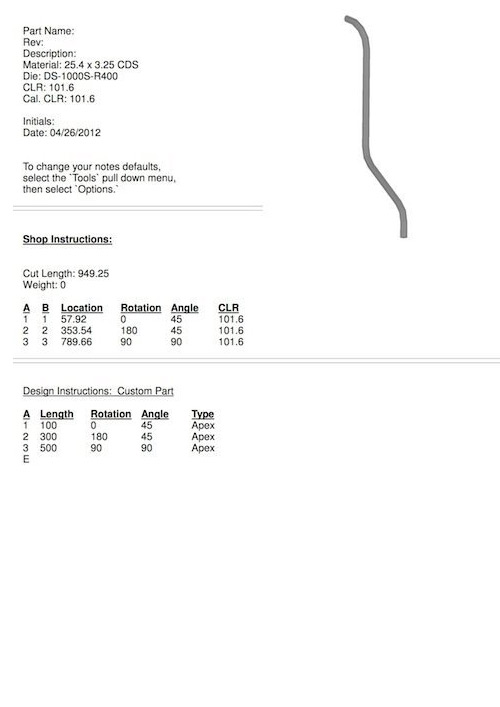

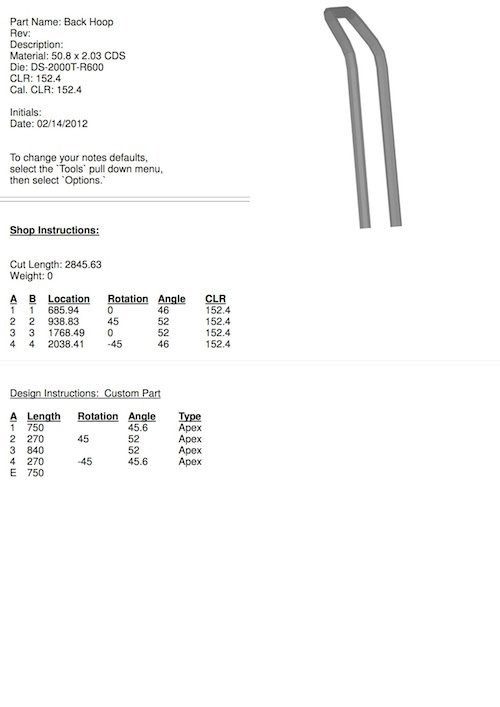

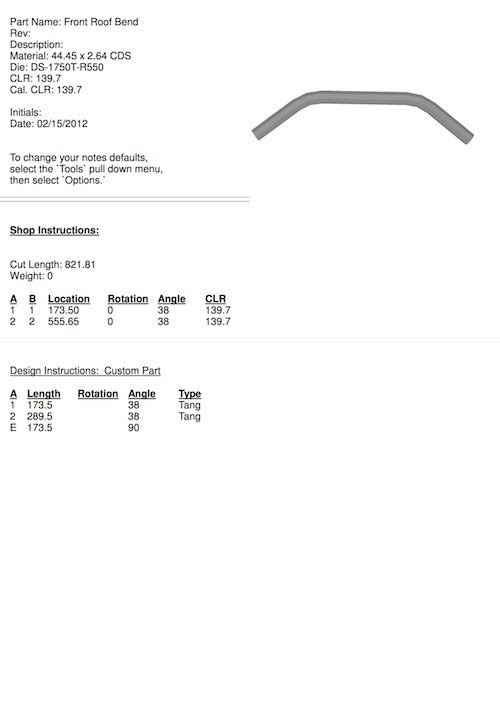

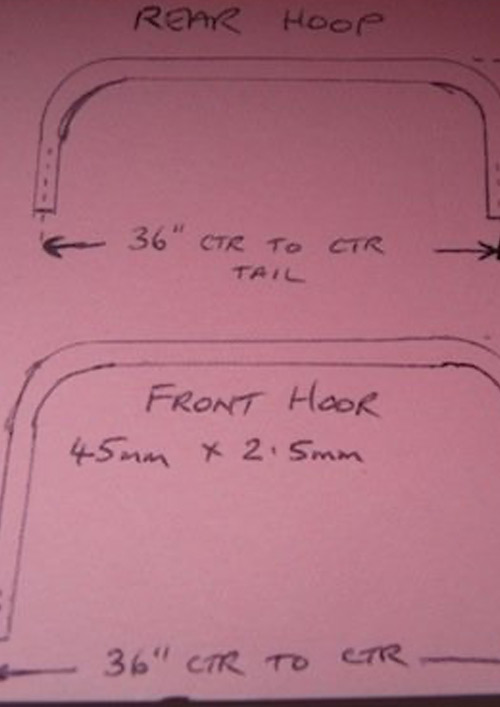

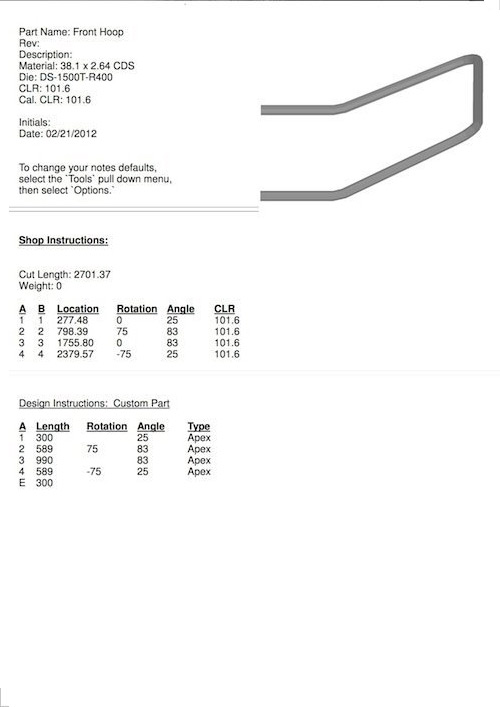

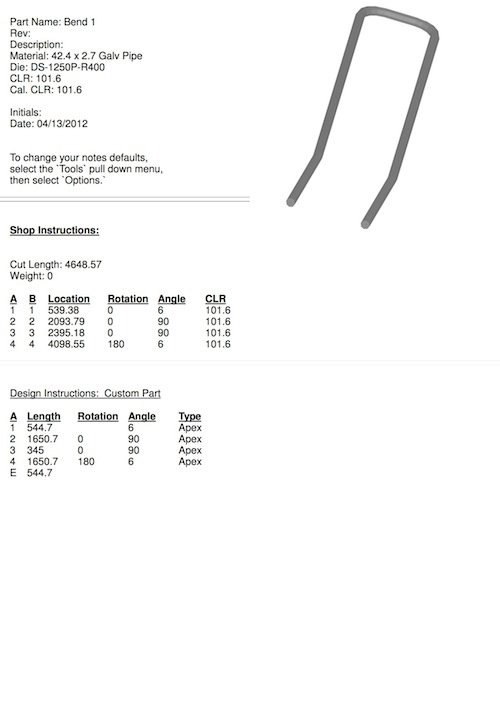

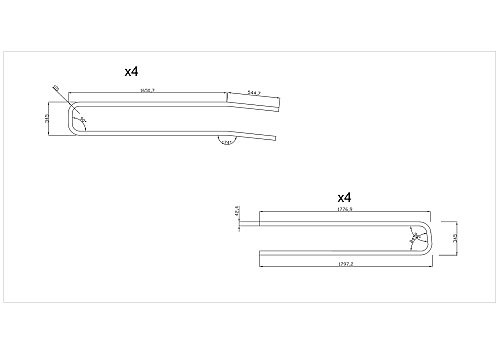

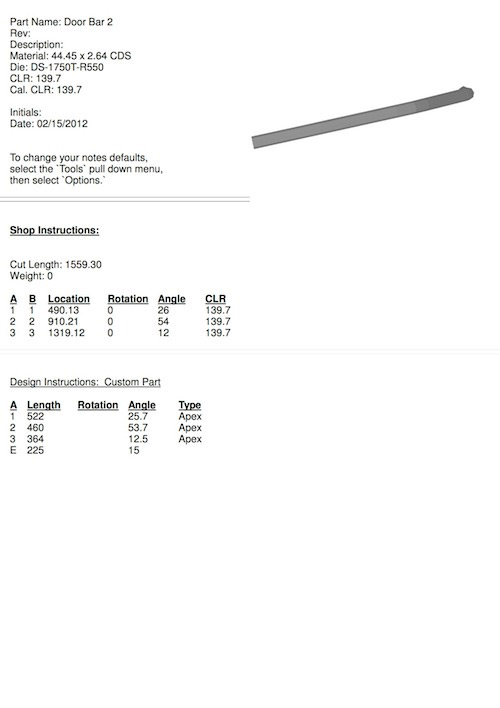

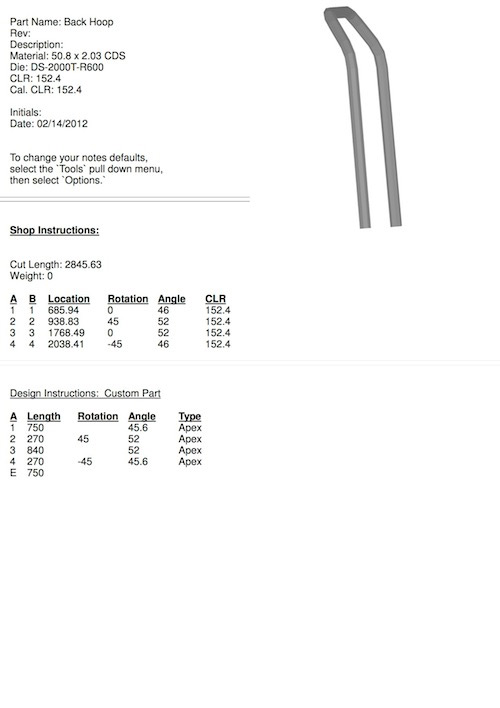

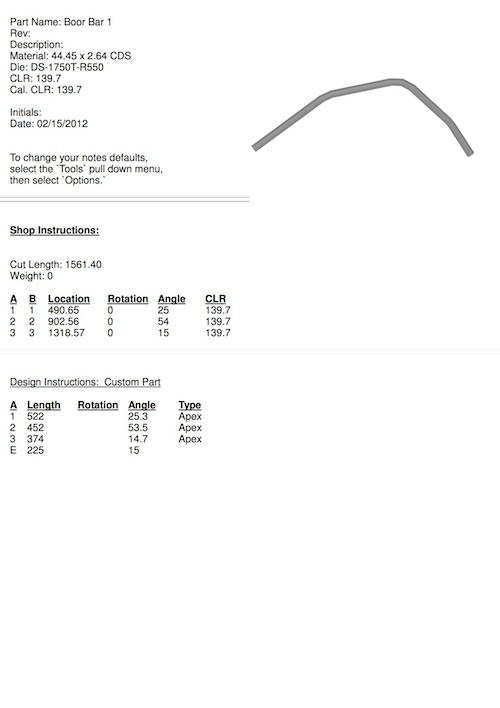

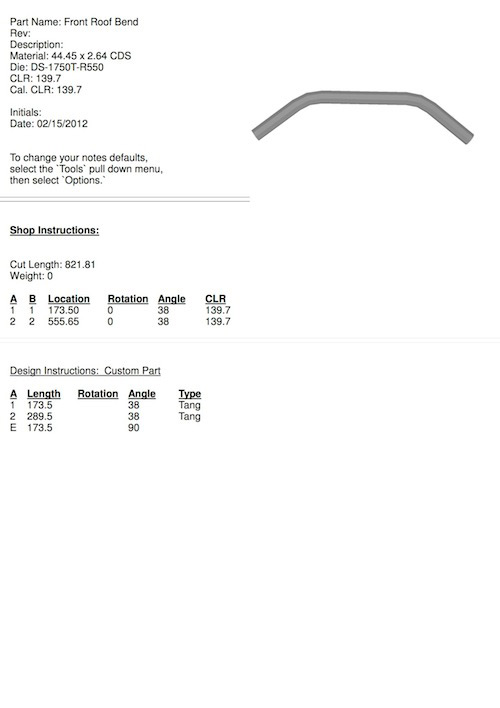

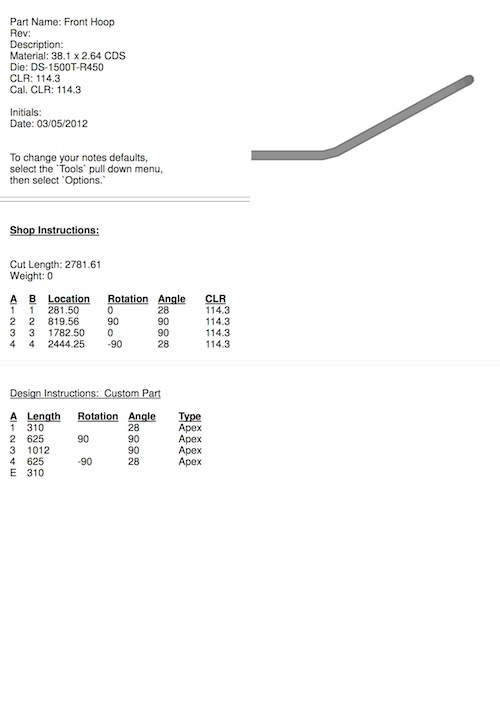

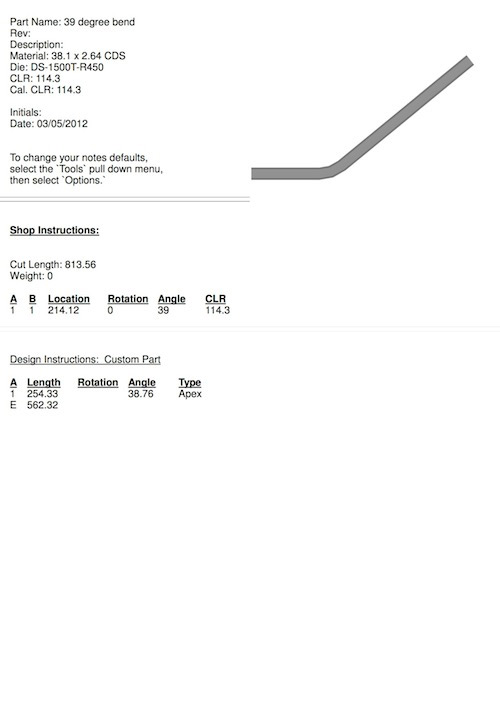

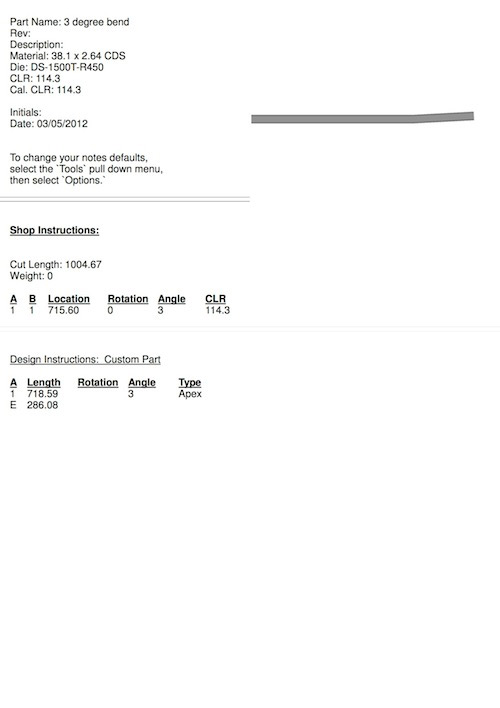

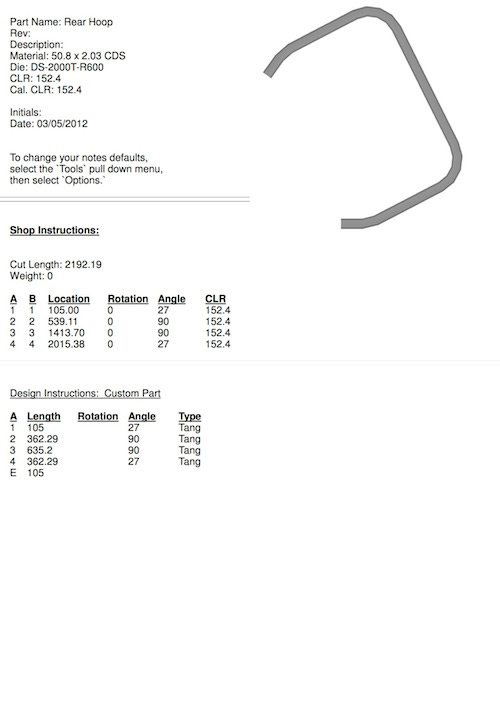

Example Plans

Latest News

Gallery

Unit 38

Boots Farm

Straight Mile

Bourton

Rugby

CV23 9QQ

Tel: 01926 633698

Email: sales@tube-bender.co.uk

Web: tube-bender.co.uk