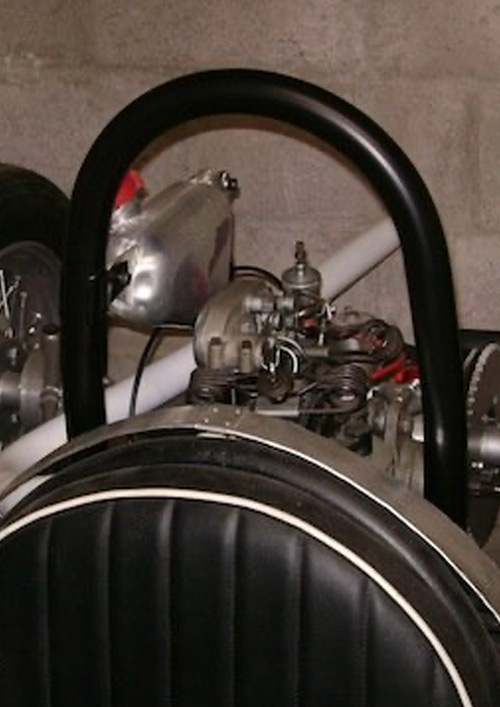

Land Rover Roll Cage

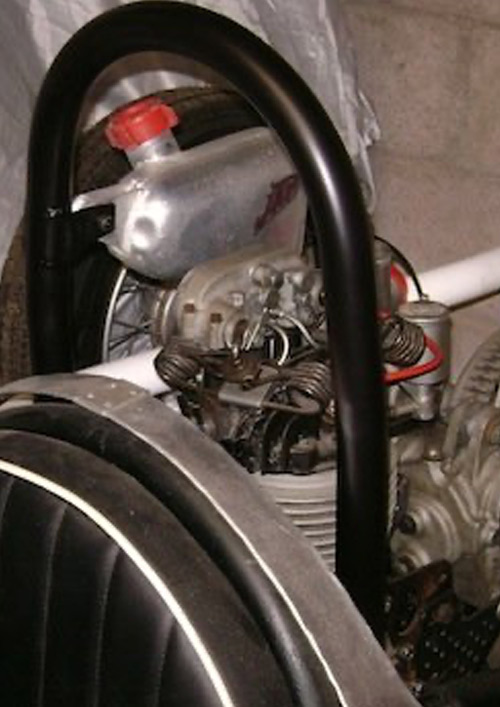

Fabricated and Fully Installed

Tube Bender Limited produce highly accurate hoops and roll cage kits using computer aided design and production fully installed at our premises or for the end user to install.

This represents considerable build savings. Check the prices in our Ebay Shop.

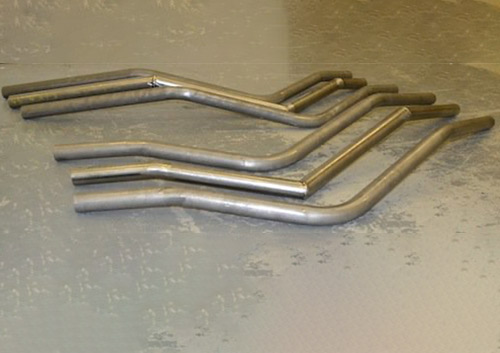

We use a CNC laser table to cut all the parts from plate (spreader plates/mounting plates/roll cage saddles). We use a 60 ton press to form all the roll cage saddles (38, 45 and 50mm OD). We use our own in house 3D modelling software to design and develop the cage. We use a state of the art Amob CNC tube bender to manufacture all the bent components. We use a 3 axis tube notcher to scallop the tube. The only parts we buy in pre made are the nuts, bolts and washers! We are a one stop shop for all you roll cage requirements.

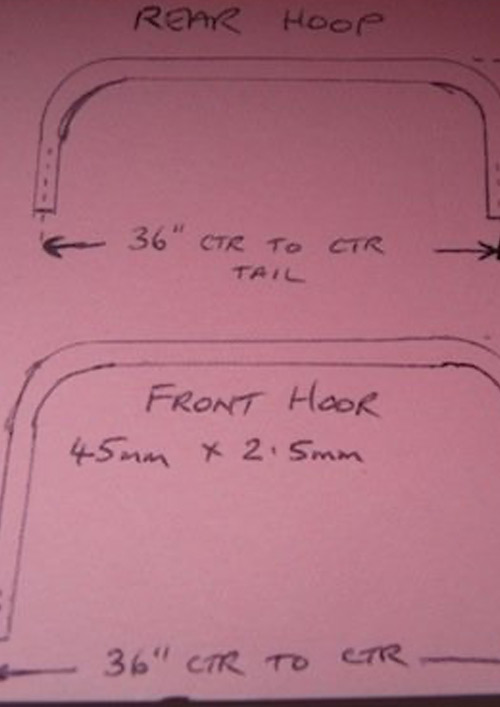

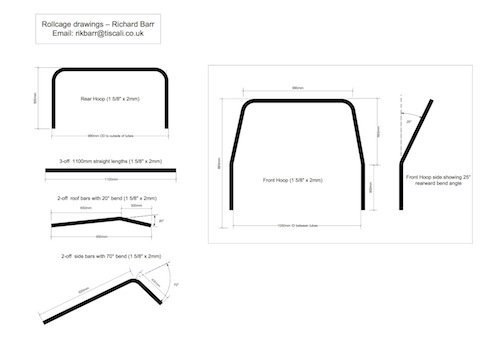

A Land Rover defender roll cage comes with the following components:-

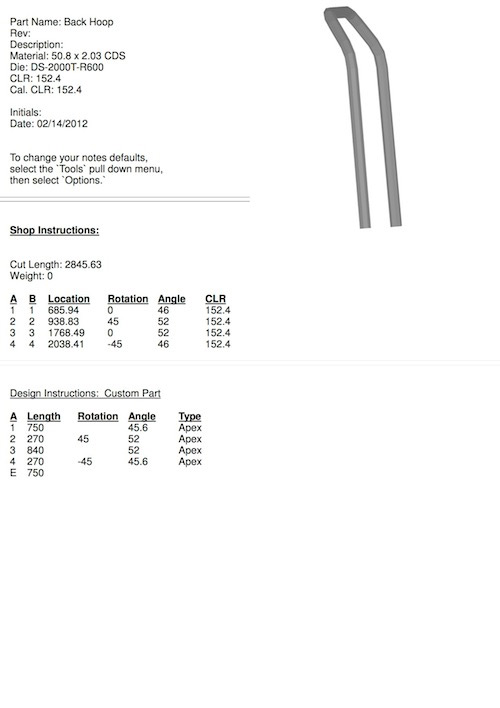

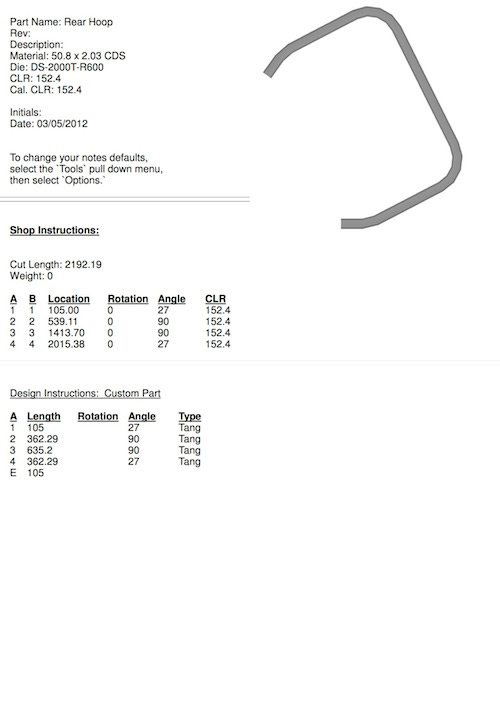

- Rear Hoop

- Rear Hoop Diagonal

- 2 x Side Bars

- 2 x Rear Stays

- 1 x Harness Bar

- 1 x Windscreen Bar

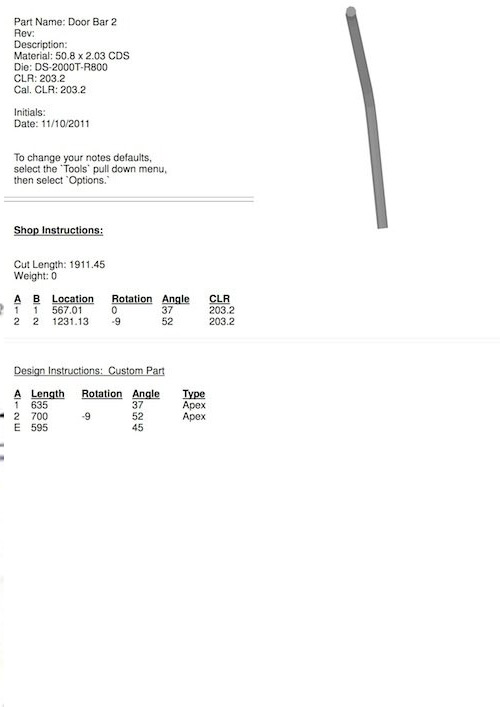

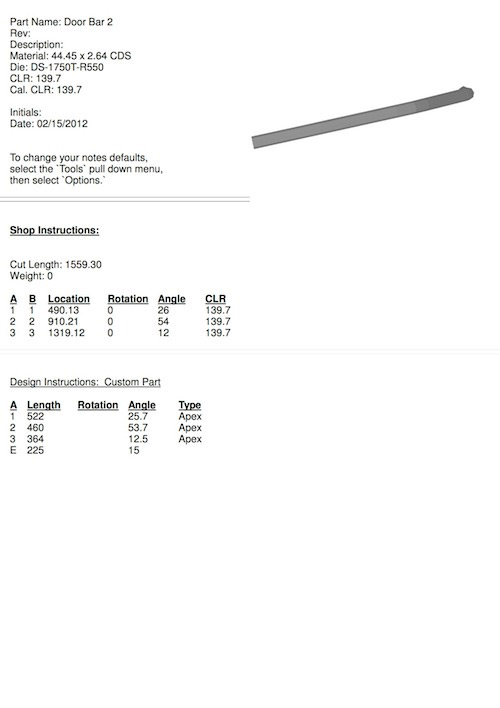

- 2 x Door Bars

- All Required Mounting Plates

- All Required Roll Cage Saddles

- Full VAT invoice

- Full Compliance Certificate for Scrutineer Pack

As we produce everything in house we can do anything you require. If you would like the cage fully welded in or fully bolt in or a mixture of weld in/bolt in this is not a problem and there is no extra cost. If you want additional optional members or more mounting points then we are happy to do this at an extra cost.

Land Rover Roll Cage Material Used

All material is BRAND NEW AND UNUSED Cold Drawn Seamless (CDS) Steel

MATERIAL SPECIFICATION – Cold Drawn Seamless Steel – Specification – EN 10305-1 (Previously BS6323 Part 4, CFS3 BK, BS980 CDS2) Minimum Yield Strength – 350 N/mm2

All our roll cages are manufactured using CDS (cold drawn seamless) tube, exceeding the minimum requirements set out by the MSUK and FIA requirements. Do not confuse CDS with inferior blue band or steam pipe used by some other manufacturers, CDS is stronger, lighter, better to weld and specifically manufactured for use in roll cages.

We have in stock all types of roll cage tube from standard CDS up to T45 and Chrome Moly and can supply this by the metre if required. Please see the items in our eBay shop.

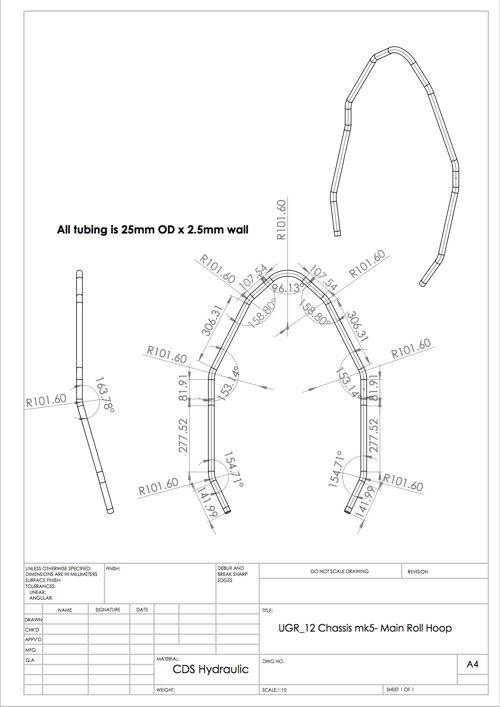

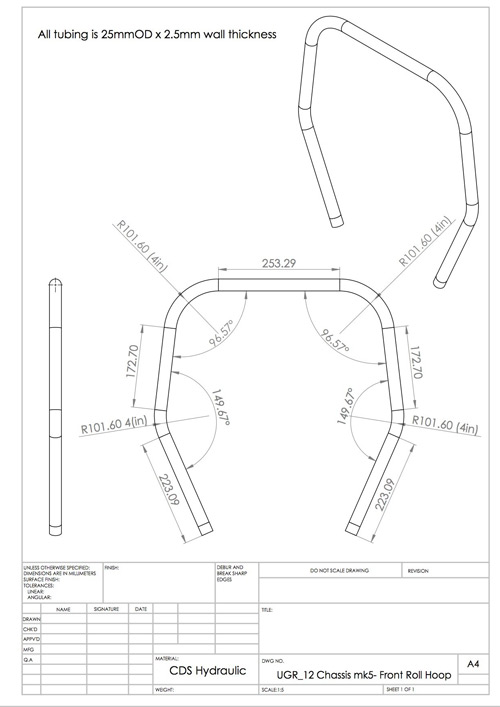

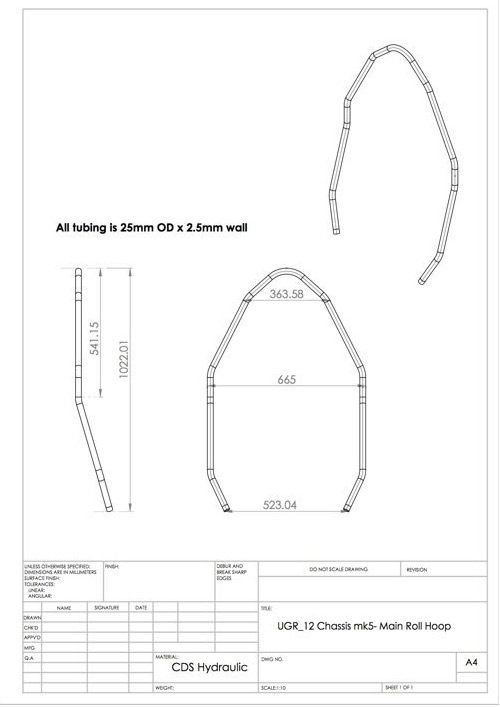

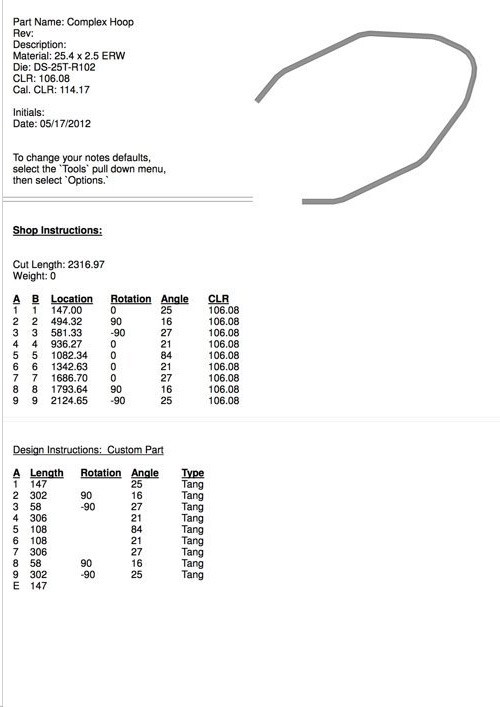

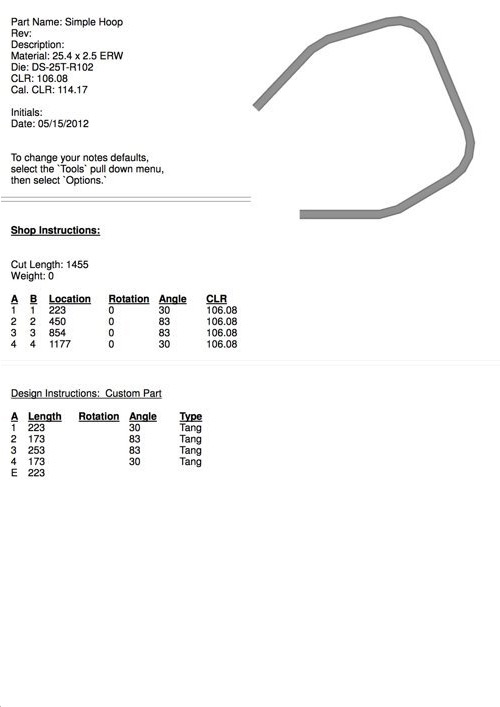

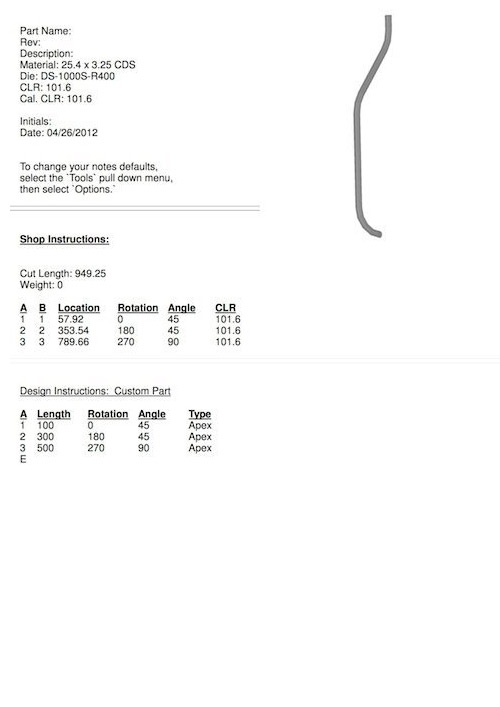

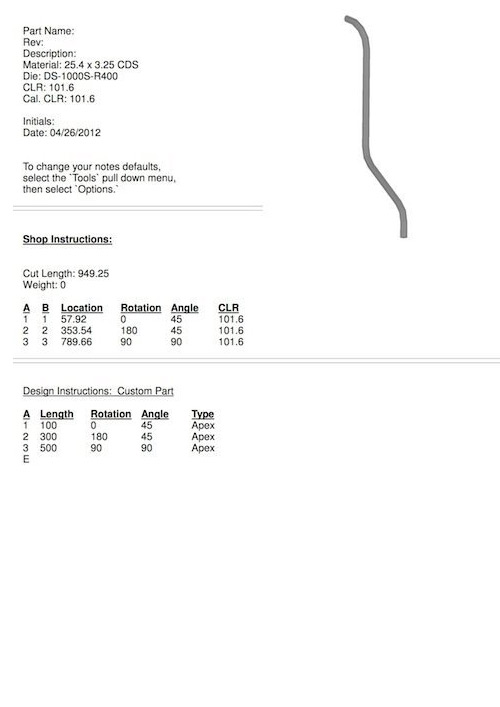

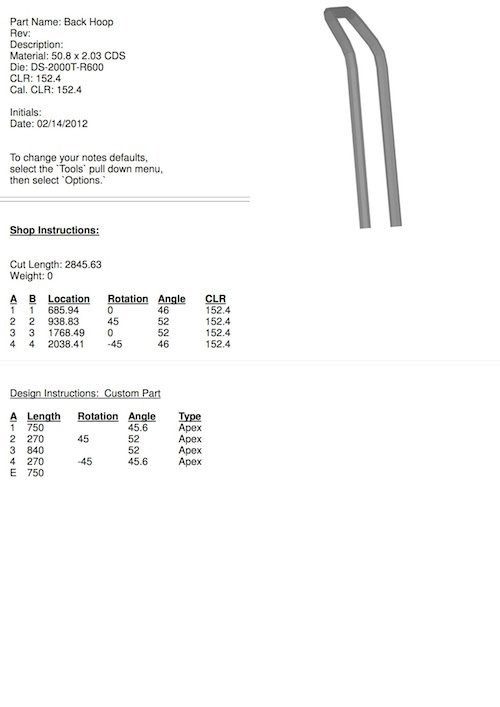

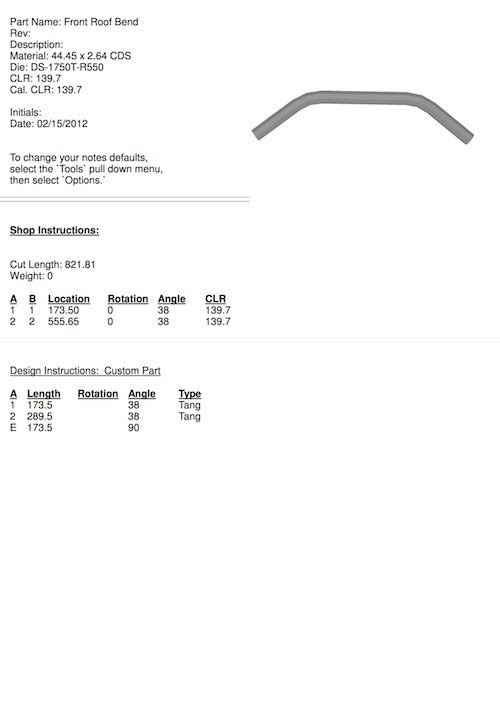

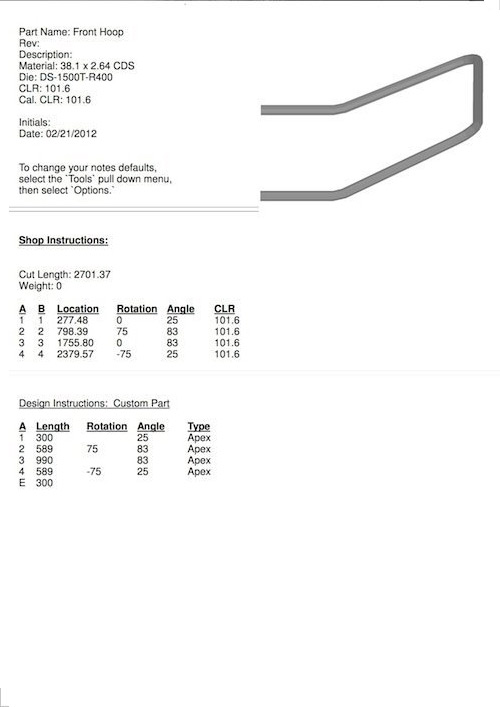

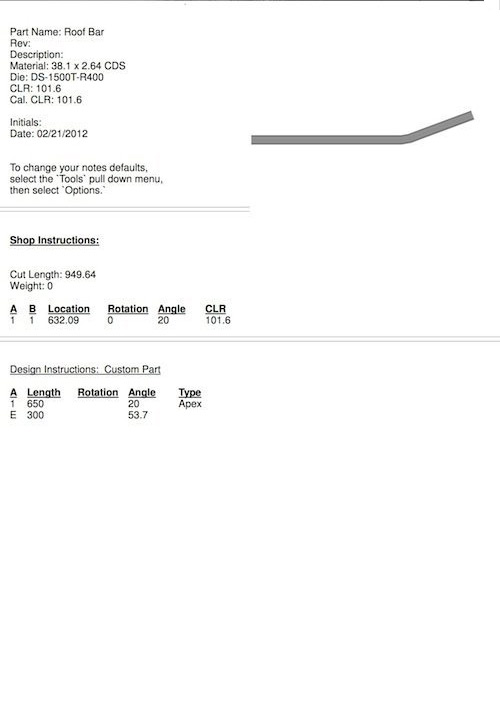

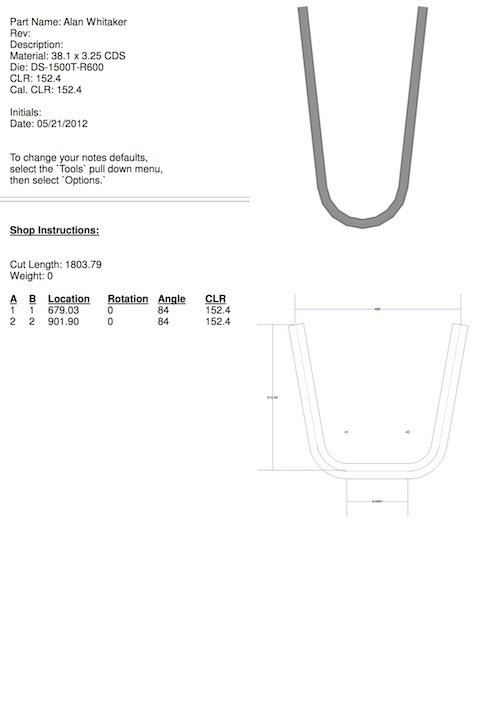

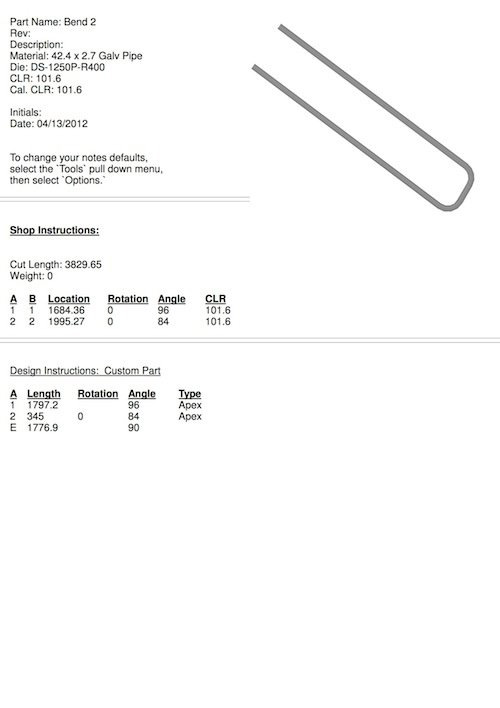

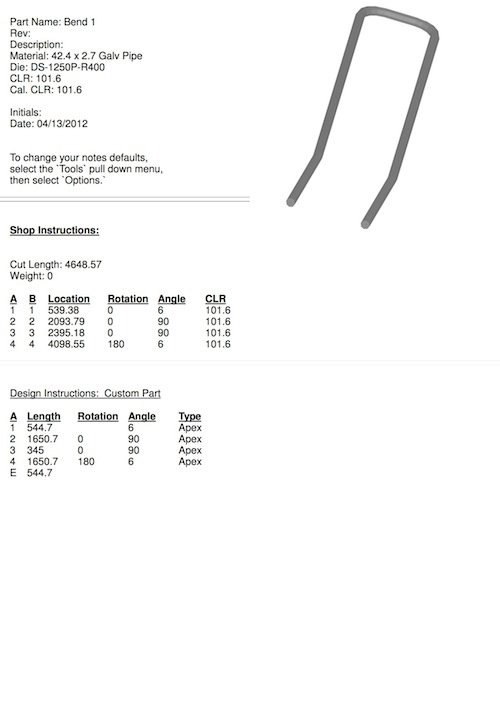

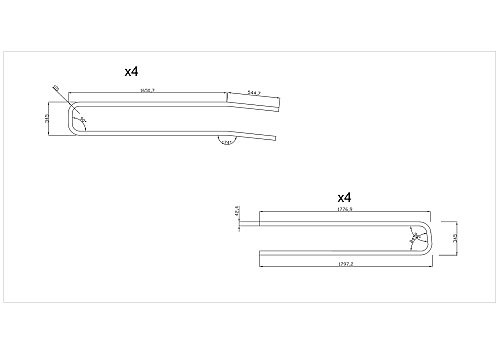

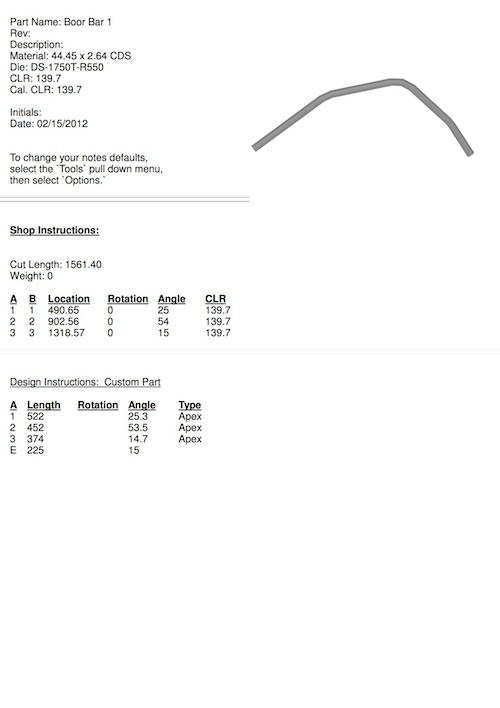

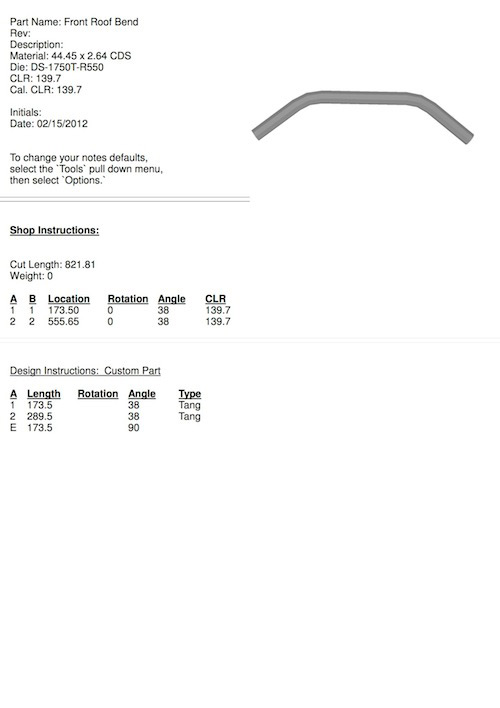

Highly Accurate Tube Bending and Roll Cage Design

The highest quality bends are achieved using one of our stae of the art AMOB CNC Tube Bending Machine accurate to +/- 0.1 of a degree. or quality rotary Draw benders, The dies used to manipulate the tube are fully machined, from a single billet of A36 low carbon steel or 1018 mild/low carbon steel depending on the CLR.

The counter die uses a 954-C aluminium bronze head with a UHMW plastic slide. Using fully-machined dies as opposed to a cast die means that the quality of the bend is better, due to cast dies leaving an imprint on the inside of the tube rather than an as-drawn surface finish.

This is just an example we can do all types and makes of vehicle. If you have ANY QUESTIONS then PLEASE contact us. We will be more than happy to assist. Please feel free to send any bespoke drawings through to us – we are very experienced in creating custom projects/applications.

PRICE GUARANTEE

For full installation or roll cage kits,Tube Bender Limited will not be beaten on price, whether it’s for one, 10, 100 or 1,000 parts! If you can email us over a quote you have received or a link to a price you have seen – we can guarantee to beat it by at least 10%!

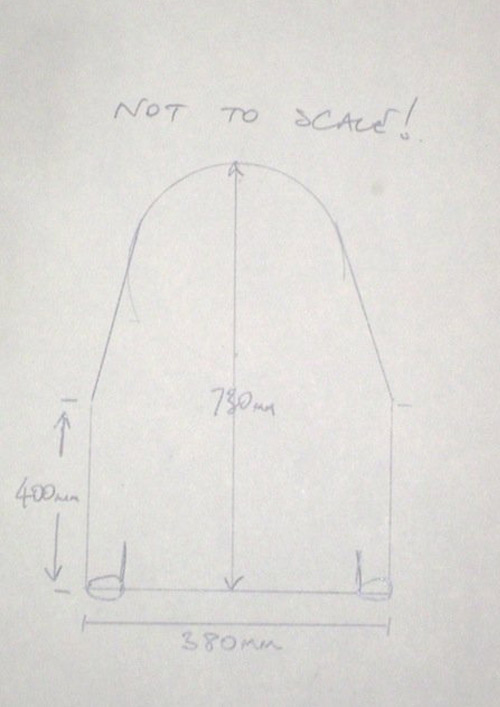

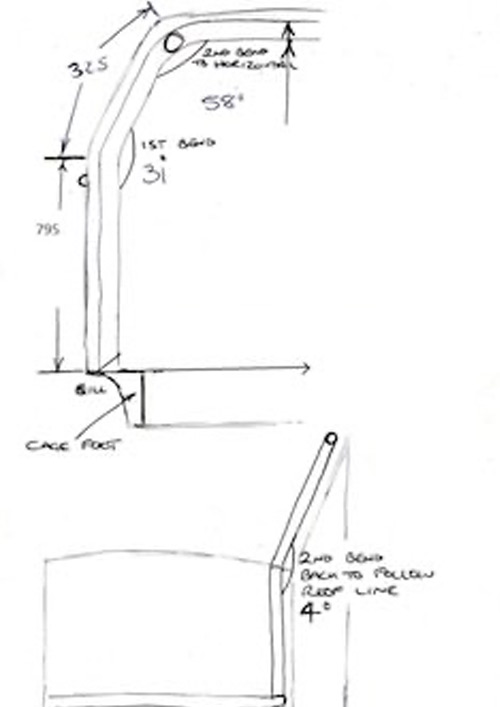

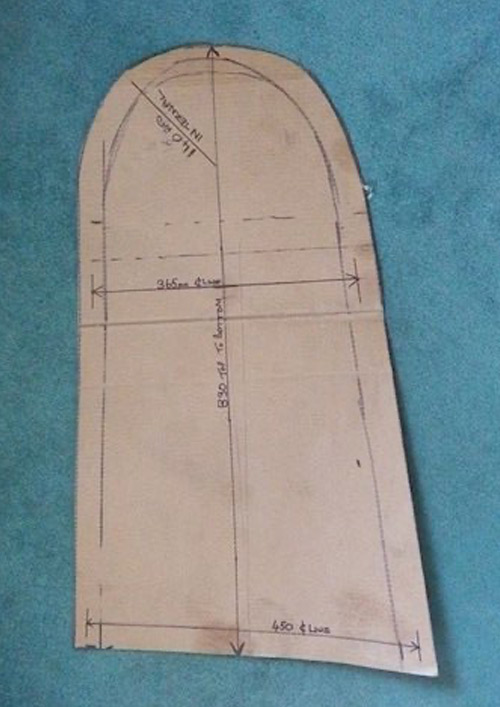

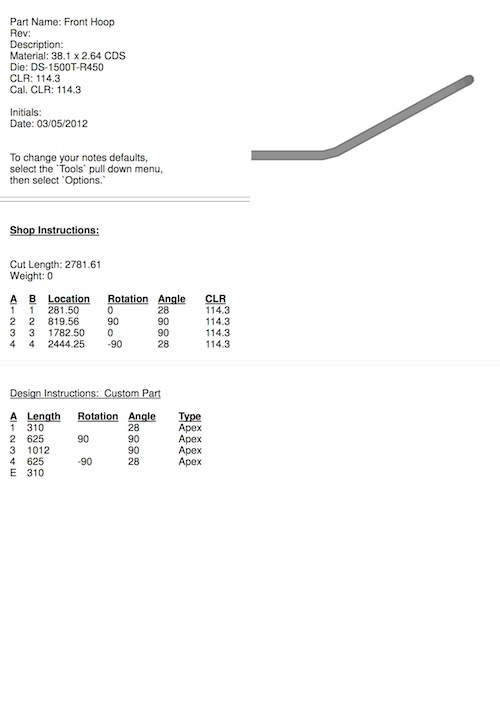

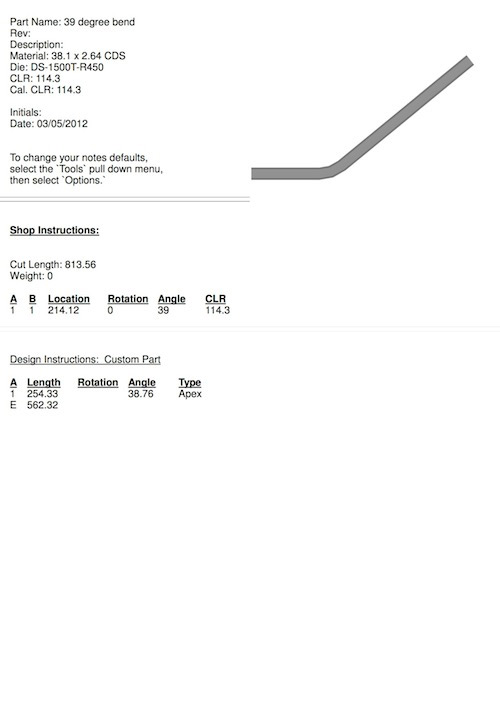

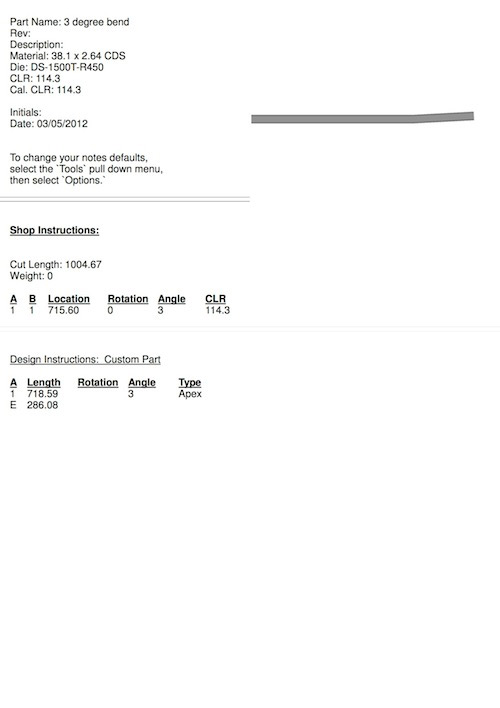

Example Plans

Unit 38

Boots Farm

Straight Mile

Bourton

Rugby

CV23 9QQ

Tel: 01926 633698

Email: sales@tube-bender.co.uk

Web: tube-bender.co.uk